Knowing what stage of Industry 4.0 you are at as a company and as a professional is very important if you want to design a structured journey!

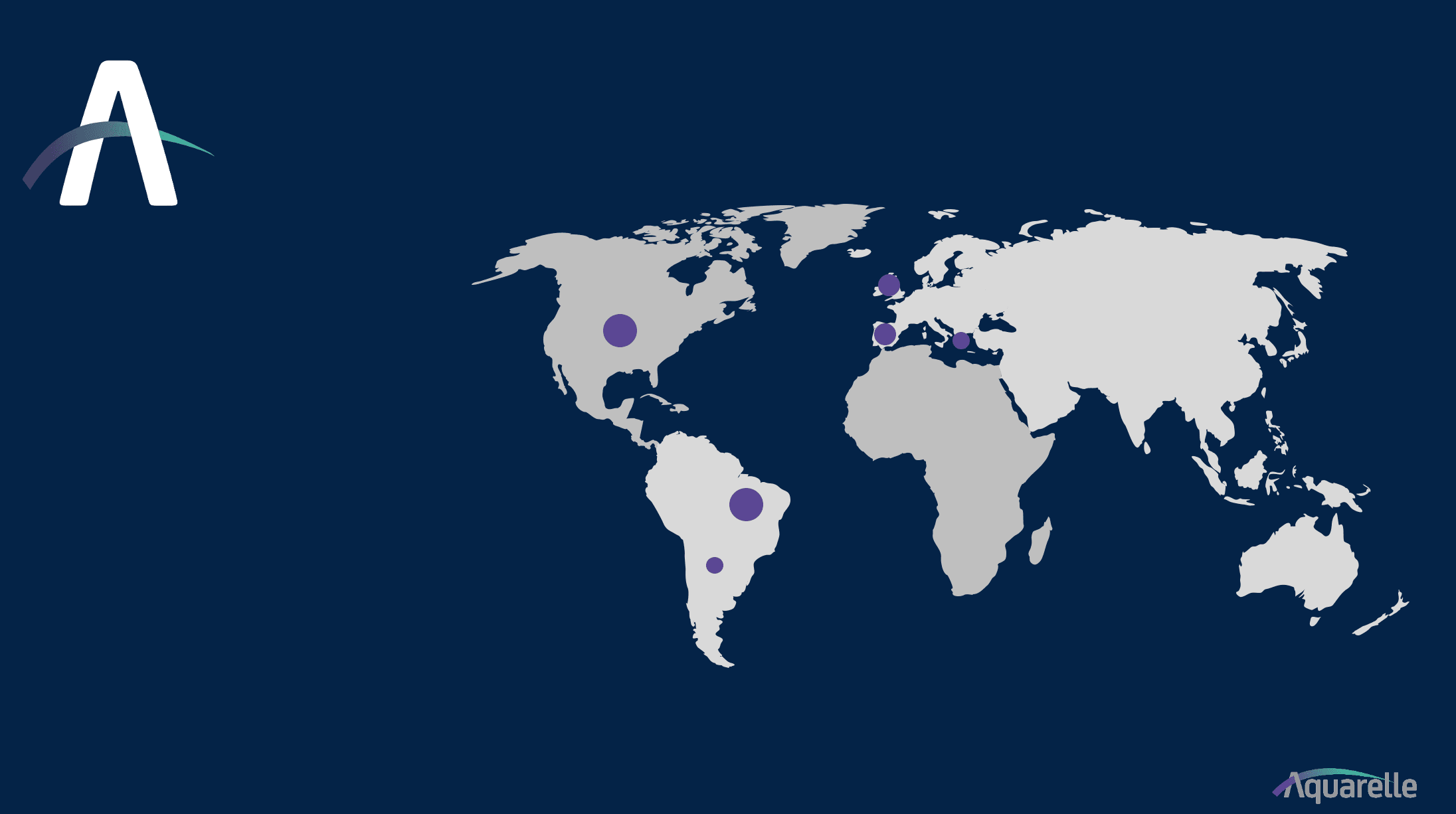

We talk and hear a lot about technologies, and I work with many of them, especially IBM Máximo, an integrated system with embedded AI, which contributes to this timeline for our clients.

An important point is the training of the professional technician, the one who is in charge of the plant or managing it, so that they are ready to work in a different way and adapt to it. Today, the market has advanced absurdly in terms of technology, but professional training has not moved at the same speed, either in terms of didactics or methodology. The professionals who have the most knowledge have sought their knowledge in the area in a "patchwork quilt" and with it have been at the forefront of transformation in some companies.

I recently read an article by FEMEVAL (Valencian Federation of Metallurgical Companies)

They are a non-profit federation that helps and promotes knowledge for companies in the Valencia region of Spain. There are indications of university training, with the Polytechnic University of Valencia and the University of Navarre, with a campus in Madrid.

I really like this interconnection between training and practice, as it mixes the academic view, which is almost always outside the market, with the practice of those who are in the corporate world on a day-to-day basis.

In this article, he mentions the efforts he has made, but the leap to digital transformation is difficult, because there is a need for training and investment and not all companies have these investments available, I'll go a little further, some are still not making this long-term projection and programming.

This investment is more than necessary, it's fundamental, a path of no return. Planning and knowing how long it will take to arrive and how it will happen is an assertive decision and should be made now!

The article also mentions a reality: we are in frantic and incredible times, where the future and the present are together and connected. There will be a profound change in traditional business models and, I would add here, in education too, because the blackboard, desk and notebook model is also seeing its days numbered. No sector is safe from this change, everyone will be impacted!

Returning to technologies, we can mention IBM Maximo itself, which I mentioned above, which is a system that has been around for more than three decades and which every year receives updates and innovations that cover the entire asset management chain, for all industries, combining AI, IoT, Automation, augmented reality, Machine Learning, Big Data, makes all plant management automatic and with online predictions, using the behavior of assets, information brought from them, making it possible to manage "at the tip of the pencil" operating costs, people, parts and plant downtime, the latter, of course, everyone always runs away from it!

Finally, they also mention technology conferences, of which there are several, including many online, which are worth following! The great advantage is that you can attend them anywhere! I'll mention a few here, but it's worth your curiosity to look around, not only in Brazil but around the world!!!

https://tecnologiasemergentes.es/

https://elemica.com/the-4th-annual-supply-chain-4-0-summit/

https://simabesp.org.br/eventos-detalhe.php?i=Mzcw

Companies must implement changes quickly if they are not to lose time, money, productivity and competitiveness. I, you, all of us are already part of this transformation!

What about you? Are you ready for Industry 4.0?